Vibration Analysis

- Home

- Vibration Analysis

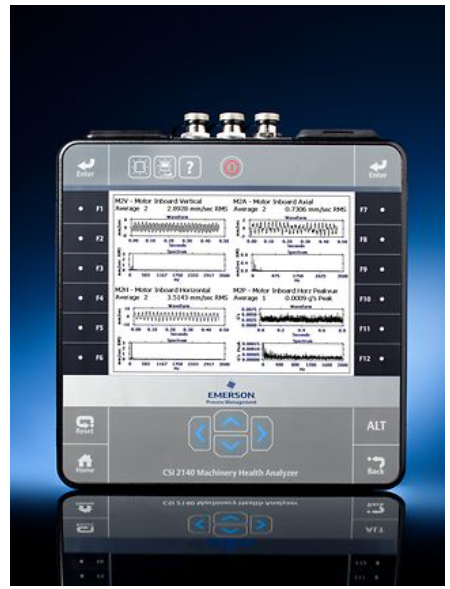

Vibration Analysis

Vibration analysis is a technique used to measure and analyze the vibrations of rotating machinery or structures to detect anomalies and assess their condition. It’s commonly used in predictive maintenance to prevent unexpected failures and extend the lifespan of equipment.

Purpose and Benefits

- Early Fault Detection: Identifies issues such as imbalance, misalignment, bearing wear, or loose components before they lead to significant damage.

- Predictive Maintenance: Allows for scheduled maintenance, reducing downtime and avoiding emergency repairs.

- Operational Efficiency: Helps in optimizing the performance and reliability of machinery.

Common Faults Detected

- Rotor Unbalance

- Coupling Misalignment

- Bearing looseness/Defect

- Structure Resonance

- Electrical/ Mechanical related issues

- Gear related issues

- Cavitation, recirculation in Pumps